The process of formation and growth of honey crystals is called crystallization. Crystallization of honey is a natural physical phenomenon that begins in any honey sooner or later. But there is no any chemical changes of the crystallizing substance. The main condition of crystallization of honey is a supersaturated solution. It’s not stable and gradually become stable and saturated by crystallization of excess sugars, especially glucose. With the crystallization the saturation of the solution decreases. If the solution is no longer supersaturated, the crystallization process is terminated. Factors which have a significant effect on the crystallization process are: sugar range of honey, water content, temperature and duration of storage, the presence of seed crystals and various activities for the processing of honey.

Sugar range of mature honey is represented mainly by glucose and fructose. Floral honeys contain about 70-80%, honeydew honeys – approximately 50-65% of reducing sugars. These two monosaccharides partly come from the starting materials or are formed from contained in them sucrose under the influence of allocated enzymes of bees. Both sugars are in different ratios in the honey . Most often fructose prevails, the amount of which is 34-41%, while the glucose ranges from 28 to 35%. New methods for the analysis of sugars showed that sugar range is very wide. But crystallization of honey is largely determined by the quantitative ratio of fructose and glucose.

The ratio of fructose and glucose is one of the options to pre-estimate the intensity of the crystallization of honey. Honeys with high fructose crystallize very slowly, and crystallized honeys tend to soften and exfoliate. Crystals of glucose move down, and the top becomes the dark, rich in fructose liquid. These honeys are difficult to sell, because they look like a spoiled product. The crystal growth rate can be even expressed by mathematical formula.

Not only the ratio of fructose to glucose has a significant impact on the course of crystallization of honey, but also the ratio of “pure” glucose to the water. If this ratio is greater than 2:1, then, of course, you should wait for the crystallization. At a ratio of less than 1.7 the honey will most likely remain liquid. Honeys with a water content of 15 to 18% show a marked tendency to crystallize, while the honey with a water content of 18% crystallizes with less intense due to the decrease of concentration of sugar. Honeys with low water content have less intense of crystallization and remain liquid longer due to its high viscosity. Generally honeys with a water content of 17 to 18% have fine-grained, soft and plastic consistency crystallization. Honeys with a very low water content in the crystalline state are often hard “like a stone”. Honeys with a high water content are softer. By mixing honey with different content of water you can get optimum humidity and achieve a good consistency.

The temperature greatly affect on the crystallization of honey. Low storage temperature slows the crystallization process, as due to the increased viscosity of honey the rate of molecular diffusion decreases. At high temperatures honey crystallizes with the formation of large crystals. If honey is stored at temperatures below -45 ° C (-49 F), then it hardens without freezing. The reason for this is the high concentration of sugar, significantly reducing the freezing point. Crystallization is also terminated, because limited molecular motion stops the formation of germ crystals. This effect can be observed in the storage of honey at 10 ° C (50 F) and below. At low temperatures the formation of crystals in the honey hardly occurs. Honeys, in which starter seed crystals were put, remained at -1 ° C (30 F) the liquid for two years. Optimal with respect to the crystallization of honey is the storage temperature from 10 to 18° C (60 F). To avoid reducing the quality of honey, it is better to stick to the lower boundary (50 F). By Dicey honeys crystallize faster at a constant temperature of 14 ° C (57 F). Storage temperature of crystallized honey has an impact on its consistency and flexibility. Lard-looking honeys should be kept in a cool place, and room temperature is more suitable for coarse honeys. Honeys of medium consistency are inexhaustible in a larger temperature range.

If honey is kept at a temperature above 25 ° C (77 F), the crystallization slows down, because the increase of temperature reduces the degree of saturation of honey glucose. When you store honey at 30 ° C (86 F) the beginning of the crystallization is delayed for months. Honey can be stored in a liquid state for a long time, if at first you sustain it for at least 5 weeks at 0 ° C (32 F) and then store at 14 ° C (57 F). Honeys, thus treated, remain liquid for two years. Samples, which were stored at 14 ° C (57 F) without cold storage, crystallized in 5 weeks. Through targeted heat treatment in which the seed crystals are destroyed, you can prevent or delay the crystallization of honey for long. Hadorn and Tsyuriher reported that crystallized honeys remain liquid for 8-12 months after heat treatment. This treatment of honey is when you briefly heat to a relatively high temperature and immediately cool it to prevent changes in quality. This method, known in the dairy and brewing production, is called pasteurization, especially widely used in the U.S., Canada and Europe. As a result of pasteurization you will not only prevent crystallization, but also destroy sugar yeast, which can cause the fermentation of honey. Pasteurization requires a costly equipment such as heat exchangers and various centrifuge with hot air supply.

Disadvantage of all these methods is that they can lead to a qualitative change of honey, especially in the case where, after heating the honey you can not quickly cool it. In Germany and neighboring European countries such techniques are not practiced.

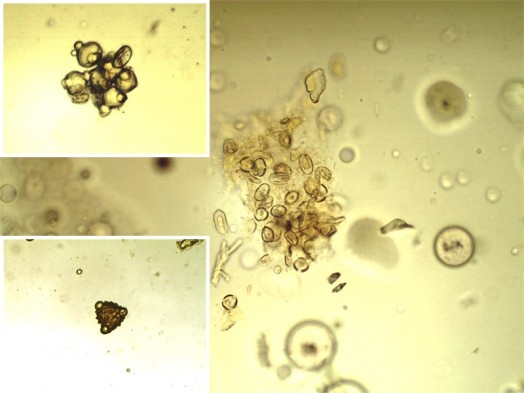

Storage time also affects the course of the crystallization of honey. The gradual decrease in the number of glucose that occurs in the process of “maturing” of honey, increases with increasing temperature, resulting in a glucose-fructose ratio changes in favor of fructose, which prevents crystallization. Honey crystallization starts with the formation of so-called seed crystals. Under this name we understand the microscopic particles such as crystals of glucose and pollen grains, which attach all the new crystals. These “primary crystals”, first of all, form on the walls and the bottom of the tank and “grow” by adding of new sugar crystals, resulting in formation of larger and larger structures, which are combined with each other. The final result is a single, solid crystalline structure with components of liquid honey between the individual links of it.

If there is no seed crystals or very little of them, they form first from glucose molecules, which combine to form tiny crystals that grow in a specific order. Since only part of the excessive amount of glucose molecules is linked by crystals, they grow in the crystal stars, like in the coarse honey. Primary crystals of glucose form mainly at 5-7 ° C (42 F), the optimum temperature for the growth of these crystals is 14-15 ° C (59 F).

Different honeys crystallize differently. Rape honey often forms small crystals with a middle or solid consistency, while dandelion honey has a very firm texture and coarse structure. Honeys, which crystallize rapidly, should not be sold in liquid form, as they will crystallize in a short time and will lose their form. Beekeeper should strive more to influence the course of crystallization, so that they become plastic and fine-grained. For this, there are two ways:

– Mechanical crushing of crystals and their uniform distribution throughout the mass of honey;

– Adding of about 5-10% of fine-grain “started honey” into the liquid honey.

Mechanical processing of honey in order to influence the crystallization process begins when extracting honey from the comb. In the process of pumping you break the existing small crystals of glucose. In small farms after removing the foam the honey is mixed by a triangular beech slat, sliding on the vessel wall with one of the planes of the slat and breaking the primary crystals. Arisen shards of crystals are evenly distributed throughout the mass of honey without getting the air into the honey. With the increase of the length of the mixing process crystallization is accelerated and graininess reduces, as seed crystals are evenly distributed throughout the mass of honey and are not able to grow to a large size.

If the honey is stored in a dry place at a temperature of 14-15 ° C (59 F) and is stirred daily, soon it will become cloudy and will get consistency of the “mush“. Once the honey starts to harden, it’s time to pour. Now honey will get a fine-grained structure and remain pliable as by mixing the communication between the crystals was broken.

The same effect is achieved by the so-called “vertical” mixing honey, when you move up and down the mounted on the metal handle plate with holes in the honey, not getting the air.

Mixing honey by hand – it’s very hard work. In the presence of a large number of honey it is recommended to get electric accessories. Specialty stores offer a range of wood and metal bits, which can be inserted in reduction gear driven by an electric drill. When buying racks and attachments you should pay attention to the fact that their surface should be protected by a plastic cover, otherwise there is a risk of getting of metal or plastic particles from the packaging into the honey.

In the U.S. and Canada usually is used filtered honey. In this honey as possible are removed the particles that cause the crystallization process, such as pollen grains, crystals of glucose and air bubbles. Lothrop and Paine first described the honey filtering under pressure using diatomite. In the future, other methods have been developed that work on the same principle. However, all of these methods must be rejected, since they require the use of high temperature. Because by using it you not only remove pollen grains and other substances, but you can change its color and taste. In accordance with the requirements of the quality of honey imposed by the Decree about honey and standards of the German Federation of Beekeepers these honey processing methods are invalid, because honey’s substances can neither be removed nor added, and the biological structure of the honey can not undergo changes that go beyond well-defined limits.

Very elegant way to prevent crystallization of honey was developed and patented by Hontarsky. In this case, all present in honey crystals of glucose are dissolved and all air bubbles and foreign substances are removed except for honey characteristic inclusions.

By using of ultrasonic and electromagnetic waves it is also possible to reduce the rate of crystallization of honey. The effect of ultrasonic treatment is based on the destruction of glucose molecules. Since in this case you damage the enzymes of the honey, this method is not suitable. The use of electromagnetic waves, in contrast, does not cause any changes in the quality of honey. Richter’s method is applied immediately after evacuation of honey. In this case, the honey goes through a certain device in which it is affected by low-frequency electric field. It is assumed that treated in this way honey remains liquid for a long time. In practical beekeeping, such a device has not found wide application.